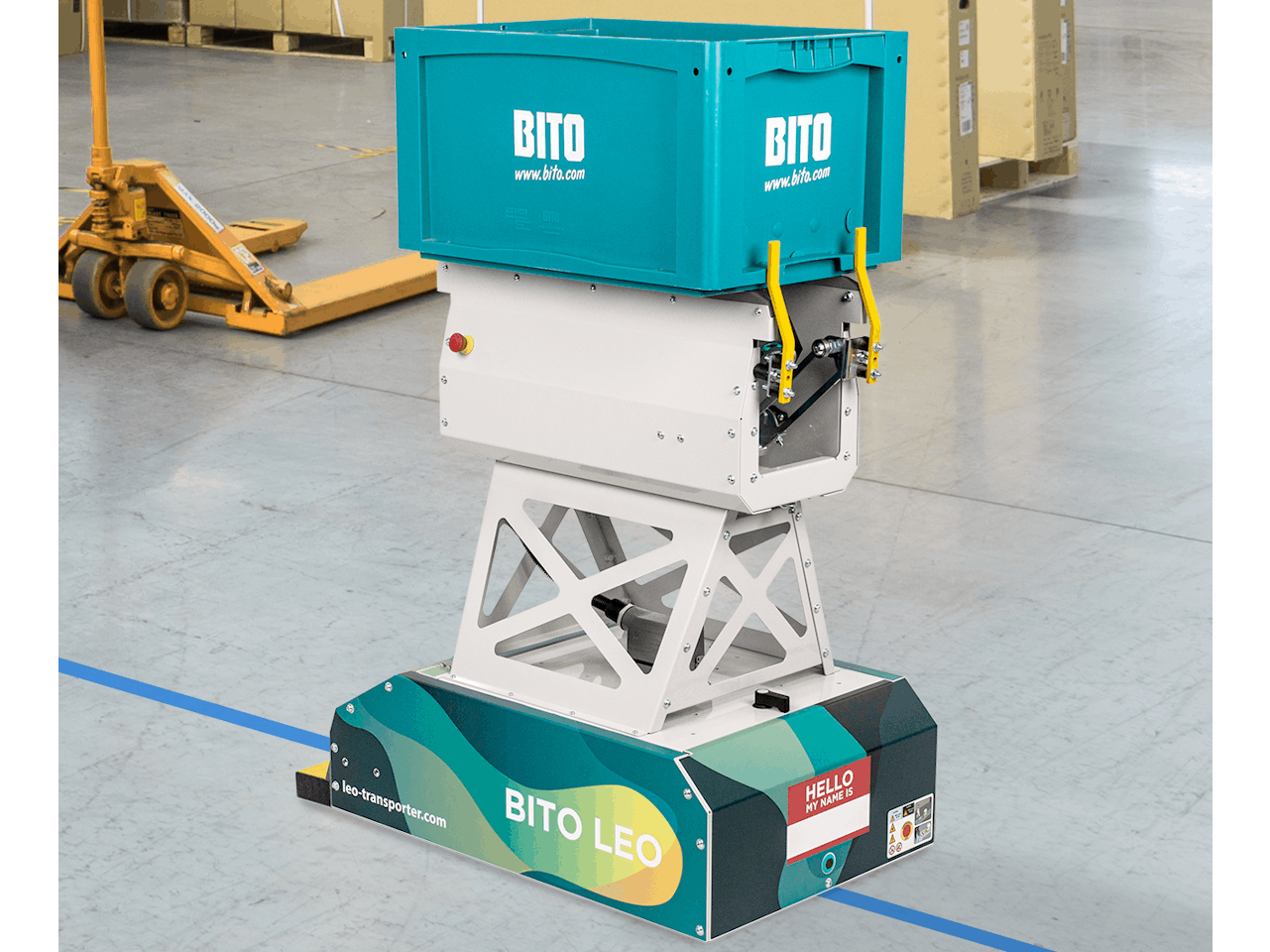

How does LEO navigate?

The LEO-AGVs navigate optically

Optical navigation takes place directly on the floor using coloured tape or paint and adhesive data matrix markers. The camera sensor technology of the LEO Transporter recognises the routes and traffic regulations. The lane guidance is also visible to people.

There is no need for extensive surveying of the warehouse or production hall or for additional markings. And there is no permanent damage to the floor.

Navigating has never been easier

- Easy implementation of the system

- High flexibility and security

- Low costs

Find out more about the navigation

How do the BITO LEO transporters navigate?

Visible markings directly on the floor

VISUAL NAVIGATION

Unlike inductive or free-space navigation, optical navigation does not require any work on the ground or the vehicle to be fitted with additional sensors or software. Navigation is carried out using coloured tape or paint and adhesive markers. Routes can be changed quickly and easily.

GUIDANCE OPTIONS

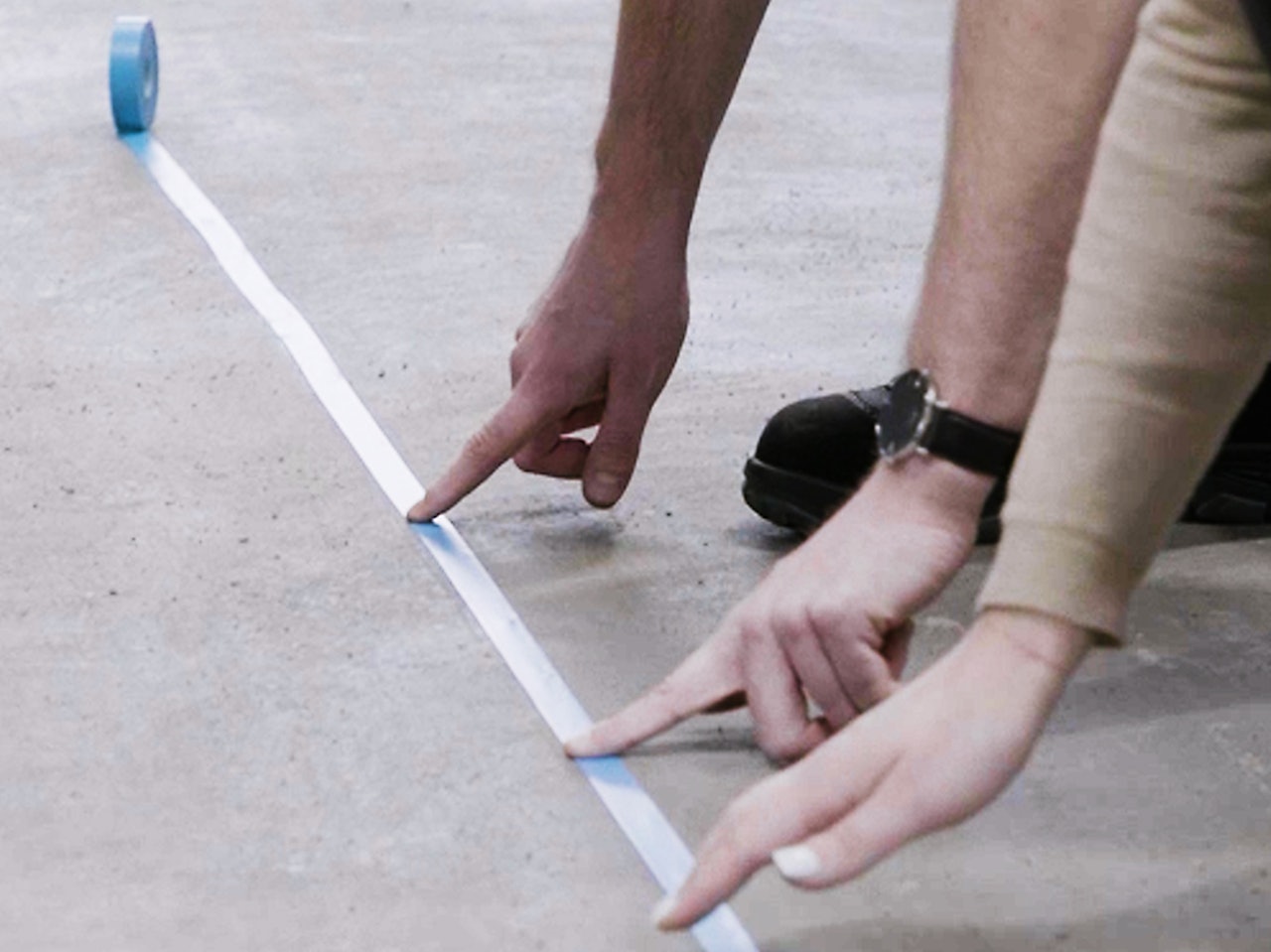

LEO's track guidance can be implemented using a variety of tape solutions or paint markings to provide the route for LEO.

TRAFFIC CONTROL BY MARKERS

Markers act as traffic and road signs. They give the LEO transporters their destinations and allow them to reduce their speed before sharp bends, for example. About 40 basic commands can be combined into a wide variety of commands.

ROBUST AND HARD-WEARING

The markings themselves are robust. They can withstand being driven over by forklift trucks and the like. The plastic coating prevents permanent damage. Dirt can be wiped off easily.

SENSORY-CAMERA

The LEO Transporter is equipped with a special camera sensor system that recognises and reads the guidance and markings and carries out the commands.

SAFE AND VISIBLE ROUTES

An optical lane is clearly visible to people, so that routes can be easily kept clear. Damage can be detected and repaired by any employee.

LEO adapts to its environment

Driving without track tape

The BITO LEO system is a track-bound, optically navigating AGV. However, the LEO transporter can travel up to 25 metres on a straight road without a track.

This means, for example, that lane damage at junctions with regular forklift traffic can be avoided. It also minimises the maintenance requirements for this section of the route.

This function is also useful in situations where LEO is driving a long straight line next to a pallet rack. The advantage here is the saving of material and labour in the routing of this section of the route.

Book an appointment!

Use our online booking calendar to arrange an appointment with our BITO LEO experts.

Layout-Anpassungen könnten einfacher nicht sein

Track guidance according to your needs

Track guidance for LEO couldn't be simpler: Attach the tape to the floor, switch on the LEO transporter, place it on the track and the system is ready to go! Warehouse or production environment, pedestrian or forklift - we have the right solution for every application.

All solutions can be combined in projects.

Variants of the LEO track tape for navigation

Spurband FLEX

The simplest and cheapest form of track marking. Suitable for low-traffic environments or to easily test new driving courses.

Spurband ROBUST

Standard tape for most applications. Robust against normal loads - also withstands floor cleaning.

Spurband ULTRA

Ideal for old, porous floors and changing surfaces. The 150mm wide tape always ensures the optimal contrast between the ground and the track.

Lacquering

The solution for permanent, high-traffic areas. The track also withstands forklift traffic, for example, and reduces maintenance costs.