BASF Logistics GmbH

Automate your inbound receiving and quality inspection operations with Autostore bin storage!

About BASF Logistics GmbH

In 2019/2020, the chemical company BASF SE Ludwigshafen built and commissioned a new technical materials supply warehouse in Frankenthal. Covering an area of 17,700 square metres, the warehouse stores everything the entire group needs in Ludwigshafen and the surrounding area to operate the integrated site with around 34,000 employees.

Background and requirements

- A new central warehouse for supplying the chemical plant receives goods of all kinds, which are checked, stored and, if required, delivered within a few hours.

- Two LEOs are already in use, connecting an Autostore container warehouse with the outgoing goods area for CEP service providers over a short distance.

- A further 300-metre route is to be automated with LEO, connecting the incoming goods area with the quality control area and the Autostore container warehouse.

Efficiency increase at a glance

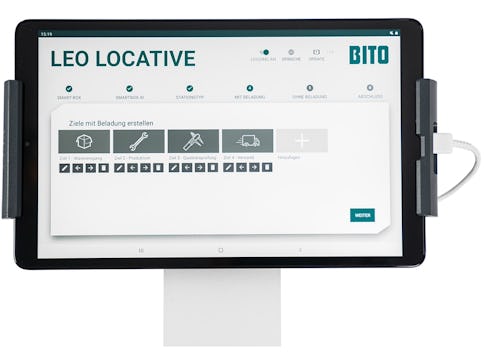

Die BITO Solution

4x LEO Locative incl. automatic charging function + Blue Spots (35 kg load capacity)

4x double station with buffer

3x Smart Box, 1x tablet, various accessories

Customer application and the characteristics of the storage facility

- Automation of the transport of incoming goods from quality control to the Autostore container warehouse

- Reducing walking distances and thus improving the use of resources

Customer benefits

The BITO solution has provided the following benefits:

- LEO saves the forklift trucks a driving distance of approx. 22 km per day

- Increased safety through reduced forklift traffic

- Thanks to decentralised control, containers can be flexibly distributed to different destinations without WiFi or IT integration

- Return on investment (ROI) within the first year