LEO supplies your injection moulding machine with empty containers

In order to produce without interruption, your machines need to be constantly supplied with empty containers. LEO can take care of this process for you! Instead of an employee, LEO automatically supplies your machines with empty containers. This frees up your staff for more important tasks, such as picking or processing your products.

Arrange an exclusive consultation appointment!

Book a free and exclusive online consultation appointment directly with our BITO LEO specialists.

Book an appointment!

Use our online booking calendar to arrange an appointment with our BITO LEO experts.

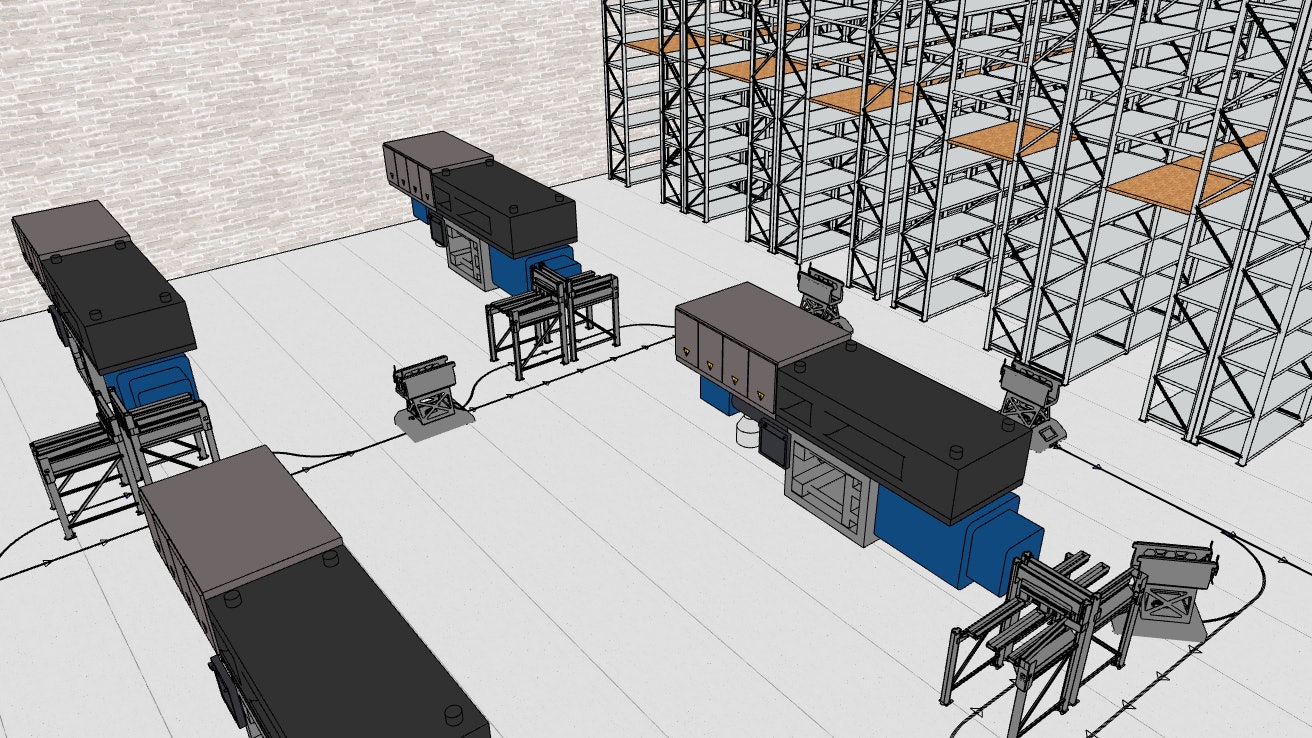

LEO connects your injection moulding machines to the warehouse

We come across injection moulded parts every day. To make production as efficient as possible, most processes are automated. However, the finished injection moulded parts still need to be moved by hand, for example, for further processing or to the warehouse. These long distances between the injection moulding machine and the warehouse are very time-consuming and associated with high labour costs. The current shortage of labour is also a problem.

The BITO LEO transporters could be your solution! The finished moulded parts fall directly into a container, which the LEO picks up with the help of a pick-up station. This means that the injection moulded parts are safely and fully automatically transported directly to the warehouse or for further processing.