Competitive advantage through automation in electrical production

The electrical industry is no stranger to automation. Whether SMD assembly, automatic soldering or optical quality assurance - you are the expert here! However, in order to produce even more efficiently, it is also important to automate the material flow between the individual placement machines and production processes. This saves your employees long walking distances and allows them to concentrate on the essentials. LEO takes care of the rest!

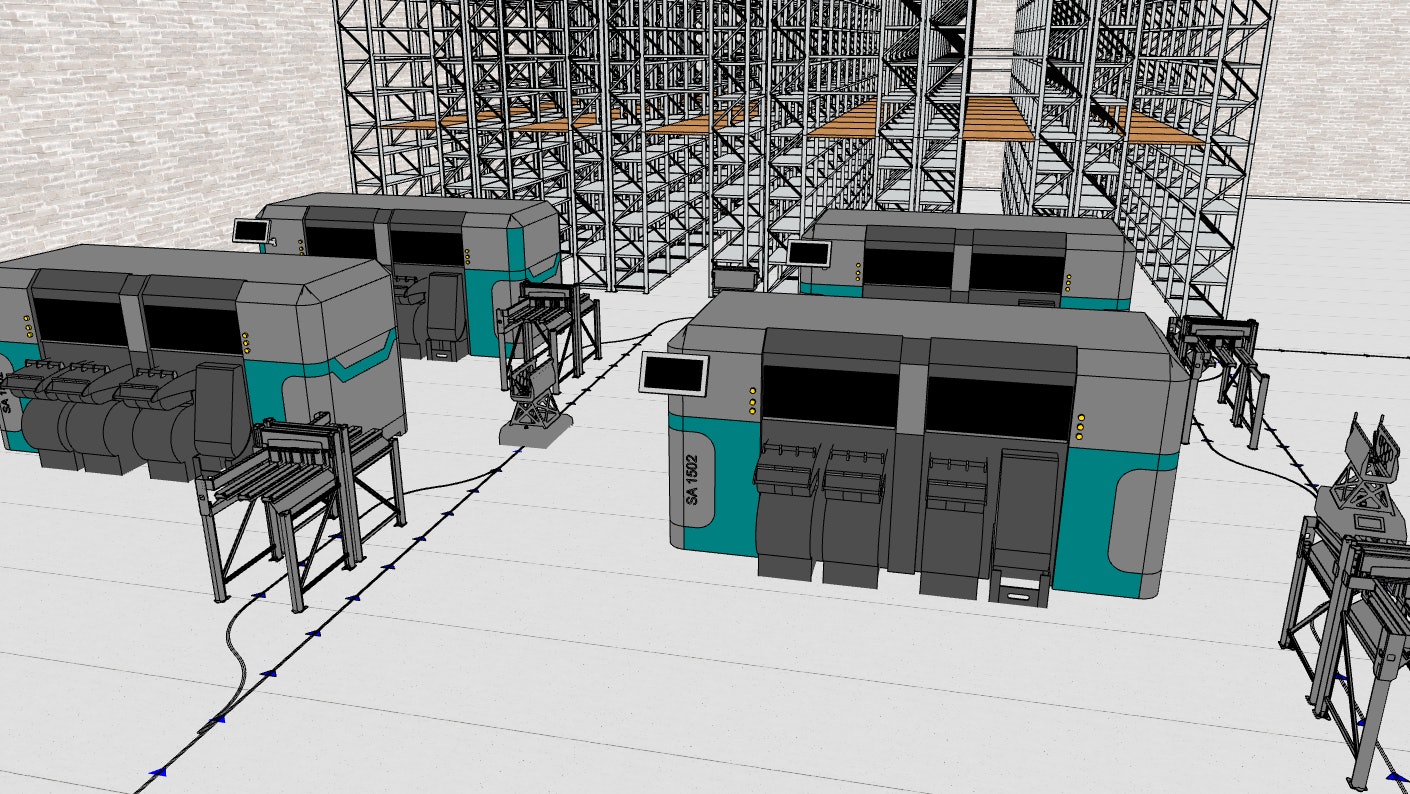

Pick and place machines must be continuously supplied with components and materials. With the help of the LEO Transporter, this supply can be fully automated, as the LEO Transporter picks up materials from the warehouse and transports them directly to the relevant pick and place machine.

You can also automate the transport of PCBs to the subsequent assembly steps, such as SMD assembly, soldering or quality assurance. This makes it possible to connect several workstations over long and short distances to ensure a reliable supply of materials to the workstations.

Book an appointment!

Use our online booking calendar to arrange an appointment with our BITO LEO experts.