Make your automated warehouse even more efficient!

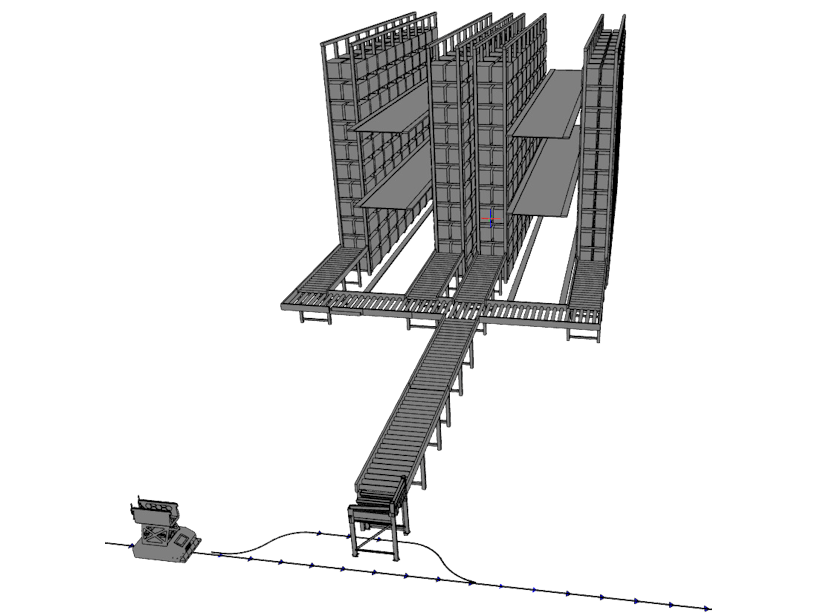

Modern warehouses are becoming increasingly automated, which is why automated miniload systems are being used. Such miniloads promise efficiency through increased automation and significant space savings. However, a small parts store still needs to be linked to the picking zone, goods inwards and goods outwards, assembly and production, for example. Material handling is therefore associated with high labour costs or investment in conveyor systems.

Book an appointment!

Use our online booking calendar to arrange an appointment with our BITO LEO experts.

LEO in combination with AS/RS

BITO LEO transporters can automatically manage this material flow for you! For example, instead of an employee manually transporting the totes from the AS/RS to the picking area, LEO can save your employees the walk. This means that your employees can spend their valuable time actually picking, packing or processing the material.

In addition, using BITO LEO transporters is far less costly and more flexible than implementing complex conveyor technology to connect the AS/RS with picking or production stations. With a high return on investment (ROI), in many cases the LEO system pays for itself within 12 months.

BITO has already proven its compatibility with automated warehouses in numerous projects. Direct communication between the AS/RS control system and the LEO system allows not only the goods to be transferred automatically, but also the destination information for the transport order.