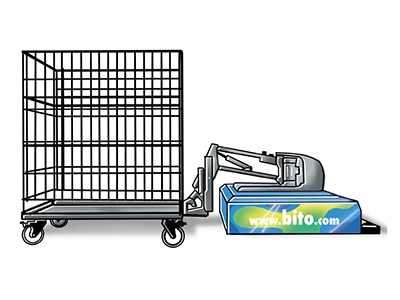

What is LEO custom?

LEO custom is a driverless transport system that is specially designed for customised superstructures. The perforated mounting plate allows the superstructures to be customised to your specific requirements. For example, you can adjust the height of the container holder or use the LEO custom as a tugger train.

- Payload and tensile load of max. 55 kg

- Electronic interface on the transporter

- 7-inch display on the LEO custom

All information about the BITO LEO

Information, tips and advice on the BITO LEO

Download LEO Profi

Discover valuable information about the BITO LEO! Download this free document and get useful tips and advice. Use this practical resource for a comprehensive overview and in-depth insights into all LEO products.

Download the document now!

Just one more click. To send you the requested document by e-mail, we need your name and e-mail address:

Leadmagnet Default Form

Done! The requested document is on its way to you.

If you do not receive the email in your inbox, please check your spam or junk mail folder.

LEO custom - customised to your process and material flow

Book an appointment!

Use our online booking calendar to arrange an appointment with our BITO LEO experts.

In which applications is LEO custom used?

LEO custom can be customised for various applications

ASSEMBLY LINE SET

LEO custom is equipped, for example, with a fixture adapted to the assembly to be produced. LEO transports the assembly from one assembly step to the next. Even longer distances between stations can be bridged cost-effectively.

TRAVELLING BUFFER STORE

LEO custom is used between two production steps. The route between the work steps becomes a buffer store. The route can also be used to define a new sequence, e.g. for product variants.

ORDER PICKING

LEO custom can ideally support multi-order picking. Ready-picked trolleys can be taken to packing stations.

LEO custom can also be equipped directly with a shelf structure and can, for example, pick up express deliveries and take them directly to the packing station.

RETURNS MANAGEMENT

LEO custom transporters can drive from returns areas to specific reworking areas or, for example, pull containers with processed goods back into the warehouse.

PRODUCTION SUPPLY

Connecting the supermarket / small parts picking with assembly workstations. LEO can, for example, pick up trolleys and drive them directly to the workstations.

Individuelle Anpassung an Ihre Bedürfnisse

How can LEO custom be customised?

LEO custom has two customisation fields. A perforated mounting plate with regular perforations allows the attachment of superstructures. A 64-pin Harting connector enables the connection of additional sensors, actuators or operating terminals to the transporter.

Who customises LEO?

LEO custom can be individualised directly by the customer as well as by BITO. Especially in the production and assembly sector, LEO is customised by the companies themselves.

BITO is happy to offer this as a service, especially for the e-commerce / logistics sector. The service includes the design, assembly and commissioning of the structure and the system at the customer's premises and ensuring the safety documentation required by law.

How is CE-compliant safety established?

The LEO custom is supplied with a declaration of incorporation as standard. This enables the customer to access the BITO risk analysis, including a description of the system limits, and to evaluate their own customisation accordingly. CE conformity is then ensured by the customer himself.

A fully CE-compliant LEO custom project can optionally be obtained as a service.

Have we aroused your interest?

Please feel free to contact us. We look forward to your enquiry:

Optimise your logistics with BITO LEO

Increase the efficiency of your production and logistics chains with BITO LEO. Our tugger train systems ensure a seamless material flow, ideal for agile production environments. In the e-commerce sector, our solutions accelerate the networking of picking stations, reduce processing times and increase customer satisfaction through fast delivery.

For special requirements, we develop customised solutions, such as holders for bumpers, which optimise your production processes. With BITO LEO, you are choosing an innovation in logistics that simplifies your processes and drives your business forward.

Visit us now to find out more about our customised logistics and production systems.